Aluminium Oxide

We keep ready inventory of various sizes of type of aluminum oxide abrasive at our offices. It is a durable, sharp cutting and long-lasting grit used in blasting, grinding, surface preparation & blast cleaning motorheads, valves, cylinders, turbine sharp edges etc. for both ferrous and non-ferrous components.

Description

Aluminium oxide media will expel stores from your substrate at double the speed than sand. This product has high toughness and hardness for industrial operations, such as cleaning turbine blades & engine parts. Aluminium Oxides quick cutting action is effective on difficult to remove debris from hard metal surfaces, as well as engraving monument markers. It is also commonly used in anti-skid /non-slip applications. Aluminium oxide abrasive grain is one of the best decision for rough sandblasting and cleaning the grain and additionally to set up a surface for painting. It is an extreme, medium thickness abrasive known to be financially savvy in shooting forms because of its recyclability, which keeps the need to habitually buy extra impacting media supplies. Also aluminium oxide impact media is known for its high thickness and precise sharpness, which makes it among the most adaptable of the impacting media types for use in dry impacting forms.

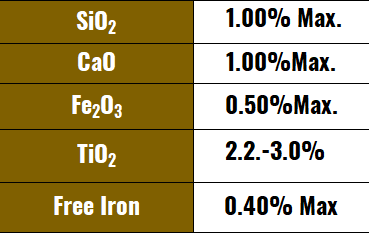

Other Impurities:

ALUMINIUM OXIDE – VIRGIN:

Abrasive Material – Corundum (Virgin Grade)

Aluminium Oxide Content – 90% min.

Hardness on MOH Scale – 09 min.

Specific Gravity – 3.9 min.

ALUMINIUM OXIDE – COMMERCIAL:

Abrasive Material – Emery, Synthetic (Commercial Quality)

Aluminium Oxide Content – 60% min. Magnetic Material 15% Max.

Hardness on MOH Scale – 08 min.

Specific Gravity – 3.6 min.

Salient Features & Application:

Fastest Cutting Abrasive

Recommended for Ferrous & Non Ferrous Components

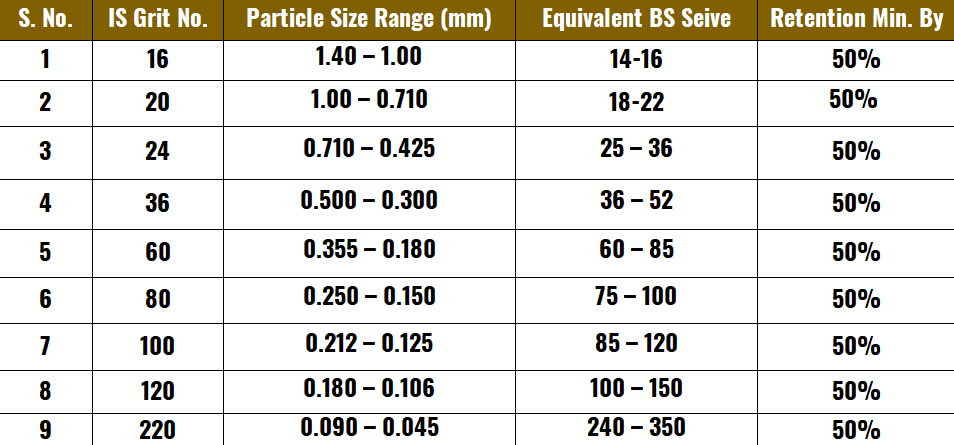

Size Chart: