Remote Control

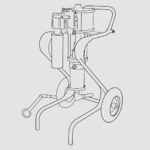

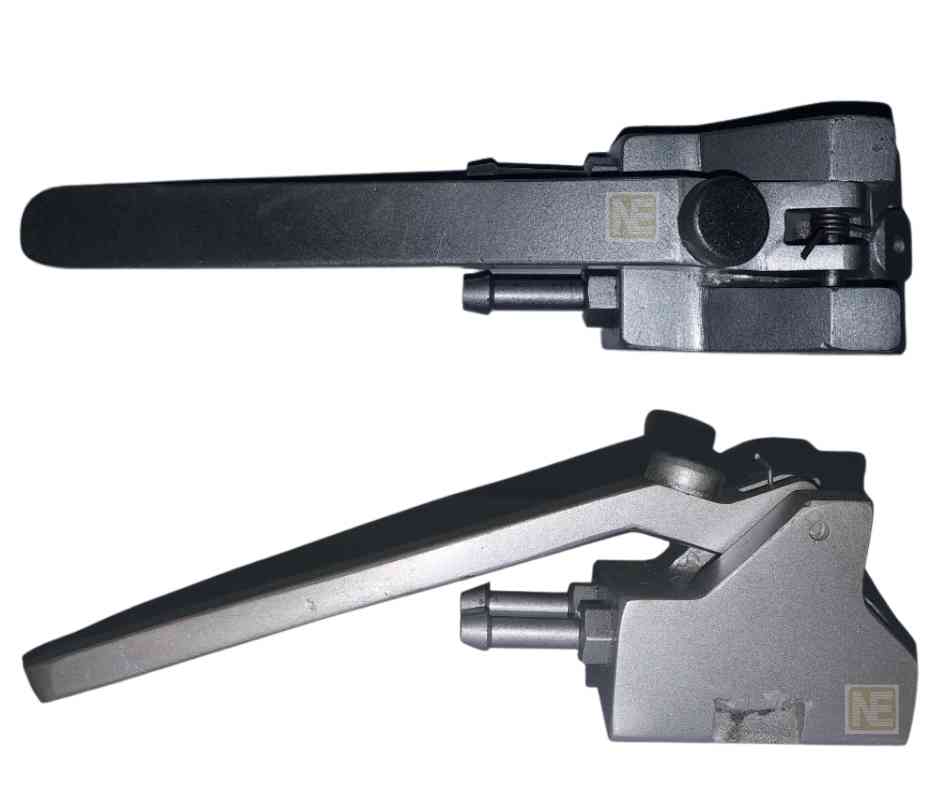

It has been observed that, occasionally due to maintaining a high air pressure of about 80 to 90 psi, the blast hose glides off the operator’s hands while changing position while blasting, which exposes the operator to multiple hazards. In order to avert this indiscretion, a remote control valve is provided with our blasting machines as a pneumatically operated safety device. Due to the Deadman handle’s spring return principle, the blasting halts when the operator isn’t performing blasting and enhances the safety of the operator. With the Remote Control System, the ON/OFF control of the machine comes in the hand of the operator at the blast nozzle via a Deadman Handle (available as ready stock).

Description

The Deadman control is activated, the piston assembly instantly shifts, opening the air inlet and pinching closed the blowdown hose, starting the blasting operation. Thus, it saves abrasives and air consumption when the operator changes position or performs spot blasting. It also enhances the safety of the operator. On top of the remote control body, the exhaust valve is housed for air venting. It controls the air inlet and exhaust functions with one valve. This unique valve is normally closed, self-sealing, and fail-safe valve. The large internal air passageway eliminates pressure loss common to other remote control systems. Key features are non-corrosive, lightweight, and long life. On top of the remote control body, the exhaust valve is housed for air venting.

We keep all shot and wheel blasting machine spares, consumables, and safety wear in ready stock. We also provide after-sales service from company-trained engineers. We also keep Steel Shots, Steel Grit, Copper Slag, Aluminium Oxide, Glass Beads & Cut Wire Shots in a wide variety of sizes and in quantity at our offices as Ready Stock.

With a Remote Control System, the ON/OFF control of the machine comes in the hand of the operator at the blast nozzle via a Deadman Handle.

(Ready stock available).

BENEFITS:

When the Deadman control is activated, the piston assembly instantly shifts, opening the air inlet and pinching closed the blow down hose, starting the blasting operation.

Thus, it saves abrasives and air consumption when the operator changes position or performs spot blasting.

It also enhances the safety of the operator. On top of the remote control body, an exhaust valve is housed for air venting. It controls the air inlet and exhaust functions with one valve.

This unique valve is a normally closed, self-sealing, fail-safe valve. The large internal air passageway eliminates pressure loss common to other remote control systems.

Key features are non-corrosive, light weight, and long life. On top of the remote control body, an exhaust valve is housed for air venting.