Welcome to national enterprises Faridabad & pune

industries we serve

Aviation Industry

Shot Peening of landing gears, spar structures, and engine turbine blades, etc. Cleaning of various components of an aeroplane also undergo sand blasting for various surface preparation rationale etc.

Automobile Industry

Sand/ shot blasting is used for blast cleaning of components like carburetors, fuel pumps, water pumps, compressors, pistons, tie rods, and electrical components etc. in the automobile industry.

Cookware Industry

Before the application of Teflon, cookware is blast cleaned. In order to ensure proper Teflon coating adherence, the oxide layer is removed from the surface and surface roughness is incorporated.

Mining Industry

Pumps, drills, pipes, and other equipment are blast cleaned before the application of sealer in the mining industry via sand/shot blasting process.

Energy and Power Industry

Shot peening of turbine blades and rotor hubs for hydro power generators. along with blast cleaning and deburring of various components of generating units and machined components.

Railway Industry

Shot peening of springs, piston cranks, heat treatment stress releving for welded diesel engine casing, cleaning of various generating unit components, and deburring of machined parts.

Marine & Ship Industry

Cleaning of valves and instruments. cleaning of electrical and electronic assemblies. Cleaning of outerwear Cleaning and peening turbine blades and values.

Electrical & Electronics Industry

Cleaning of turbine rotors. Cleaning of connectors, valves, instruments, and sensors cleaning of rotors and connectors after use.

Tyre & Rubber Industry

Cleaning of moulds and dies for the manufacture of new and recapped tyres. Cleaning of moulds and dies for other rubber products.

Stone & Marble Industry

To blast clean the surface of floor tiles, slates, sand stone, or marble chips for proper bonding with the surface.

Glass Industry

Cleaning of moulds and dies frosting, monogramming, and etching.

OUR pRODUCT cATEGORIES

ABOUT US

We, National Enterprises, were established in the year 1991 and specialise in manufacturing, super-stocking, exporting, and trading a diverse range of items. With our unwavering dedication towards success, National Enterprises, as an organisation, has carved out a niche in the industry. We have implemented an effective, comprehensive quality management system in order to ensure that our product line meets the highest quality requirements.

Our organization's key strength is our workforce, which has allowed us to cater to a large variety of customers from all over the world through a wide-spread distribution network in locations including Pune, Kolkata, Mumbai, Chennai, and Hyderabad. Furthermore, not only do we have local representatives in Jaipur, Amritsar, Ludhiana, Kanpur, and Allahabad, but also our worldwide network stretches to the Indian Subcontinent, East Asia, the Middle East, and South East Asia.

Our vendor base includes some of the industry's leading brands in their respective industries, such as Graco Inc. USA and VR Coatings P. Ltd., Pune, and our company has effectively attained an enviable place in the industry under the able guidance of its founder, Mr. Deva Mirchandani. His immense knowledge of this industry and tremendous business acumen have assisted us in facilitating suitable solutions to our clientele's varied requirements.

PRODUCT PORTFOLIO

Features:

Durable High performance Corrosion resistant Abrasion resistant Less maintenance

Our diverse range of products includes a whole spectrum of:

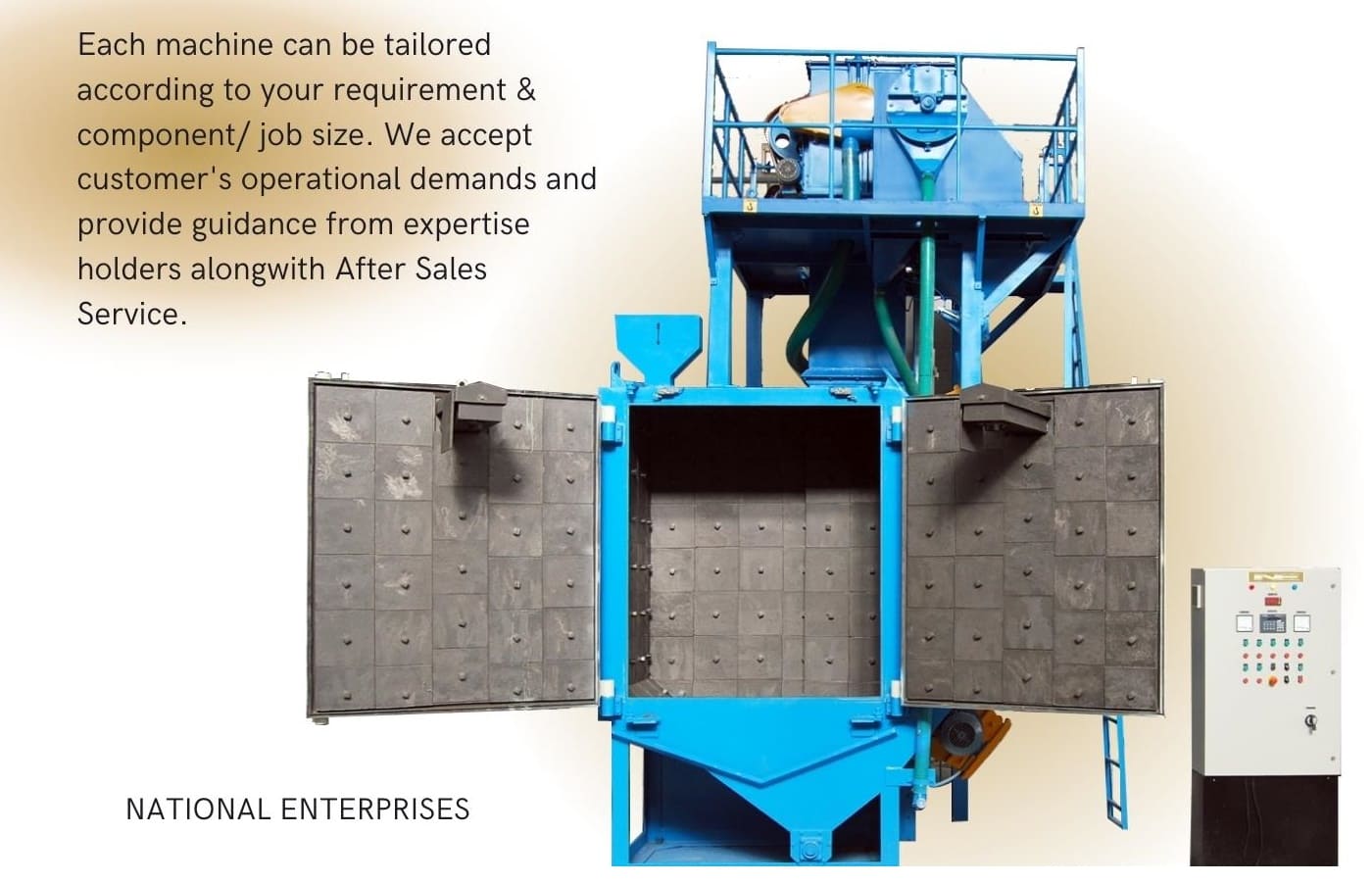

Sand Blasting Machines/Portable Blasting Machines/Abrasive/Shot Blasting Machines, Spares, Consumables & Safety Wear.

Industrial Dust Collectors

Paint Spray Booths

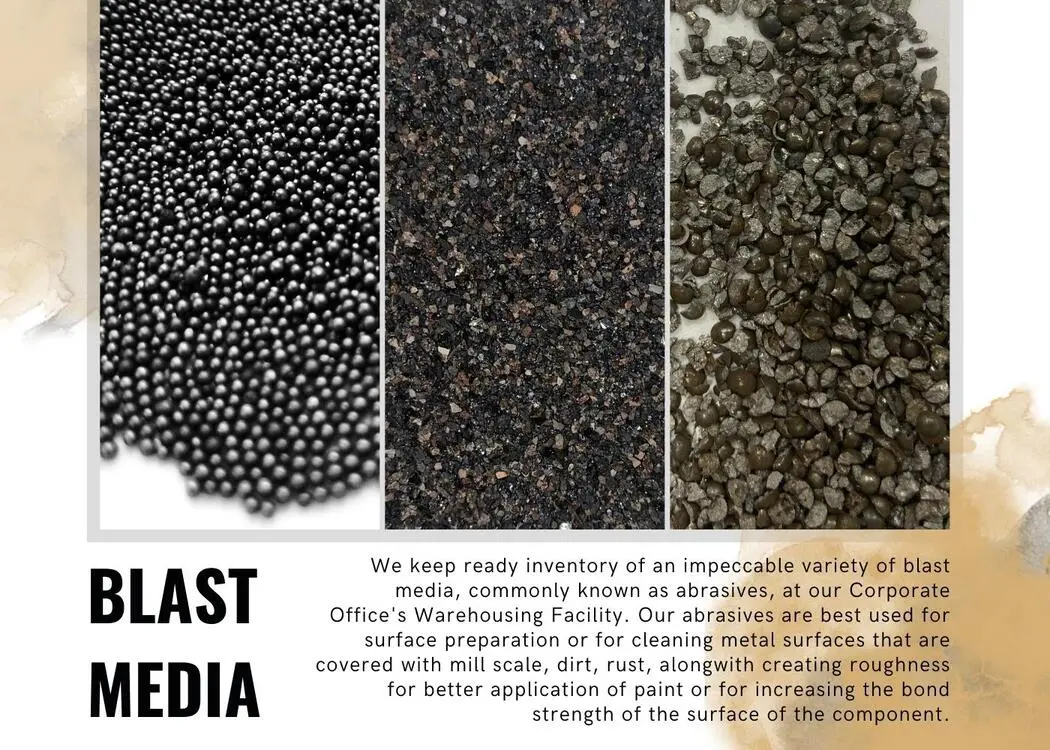

Abrasives for Blast Cleaning & Finishing - Iron & Steel Shots, Steel Grit, Glass Beads, Aluminium Oxide.

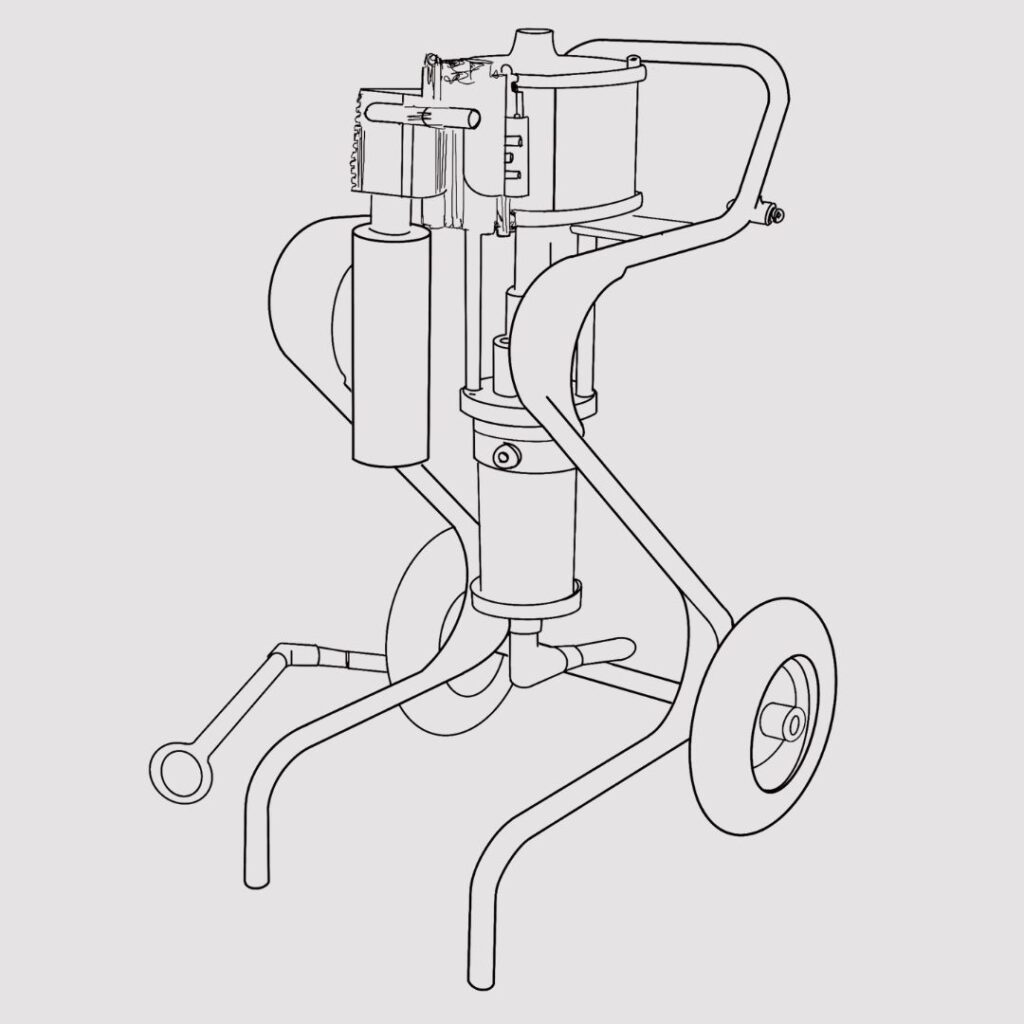

Airless (Pneumatically Operated) Spraying, Painting, Dispensing, Dosing, Proportionating Equipment

Airless (Electrically Operated) Spray Painting Equipment.

Spares, consumables, and many other products.

Why Companies Trust Us?

Client Centric

We are a client-centric organization, and we endeavors towards achieving the total customer satisfaction.

Fair Order Execution

Our diligent team of professionals works together in tandem with clients to understand their various requirements and providing them specific solutions.

Quality Products Only

Since our establishment, we have maintained the quality as the forte of our organization.