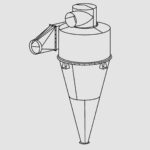

Cyclone Type

Industrial dust collectors are mandatorily required to meet the pollution control norms for keeping the environment eco-friendly.

A dust collector separates any metallic dust particles from the blasting, painting, buffing, and grinding facilities and allows the circulation of breathable air in the vicinity.

We provide quality after-sales service.

Description

A cyclone dust collector is to separate any metallic or other dust particles from the spray-painting booth or blast rooms discharged into the clean atmosphere. In this type of dust collector, a suction is created by the exhaust fan, causing the dust-laden to enter the cyclone dust collector. The dust particles are separated by a centrifugal force/action and settle in the dust tray at the bottom of the cyclone dust collector. The dust-free air escapes into the atmosphere through the exhaust fan, thereby allowing the remainder to be taken out manually from time to time.

Cyclone dust collectors, which are also known as Dust Seperators, are used to separate abrasive from dust debris, the abrasive having more density than the dust debris. The cyclone dust collector system uses centrifugal force to collect and direct dust debris towards the collection bin, which is positioned at the bottom.